Braille embossing on packaging is crucial for the blind and visually impaired as it allows them to access information independently, promoting a more inclusive and empowered lifestyle.

The WHO survey estimates that there are 300 million visually impaired people worldwide.

Besides pharmaceuticals, Braille finds applications in the travel industry, food packaging, cosmetics, FMCG, consumer durables, and more.

Braille embossing is the process of generating printed material for the visually impaired using a braille writing system. It's typically done with a braille embosser, a specialized printer that presses dots onto packaging material.

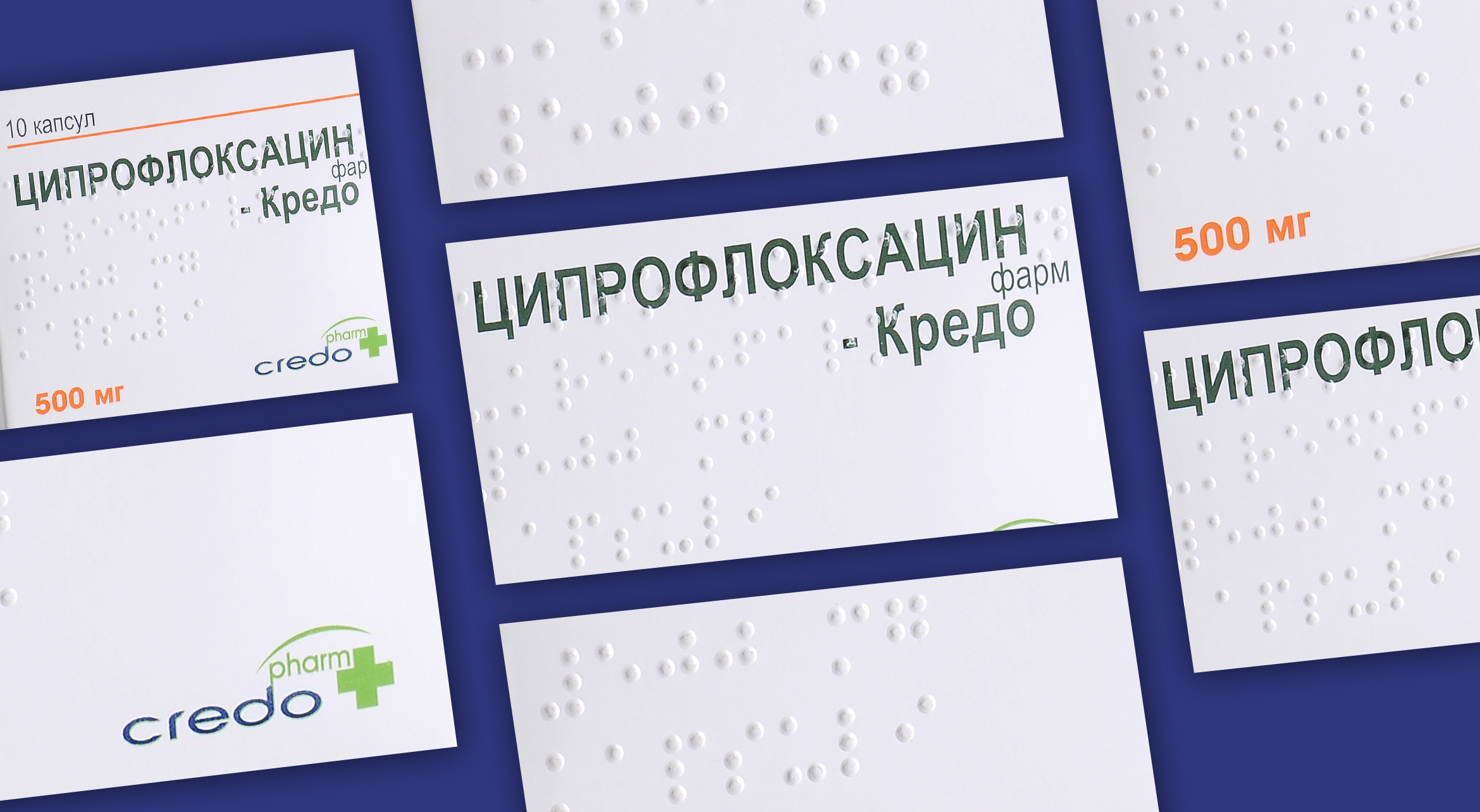

Braille embossing affects labor and costs for printing companies. It requires careful consideration of dot variations for different languages, dot diameters, offsets, and line distances to ensure easily touchable Braille dots.

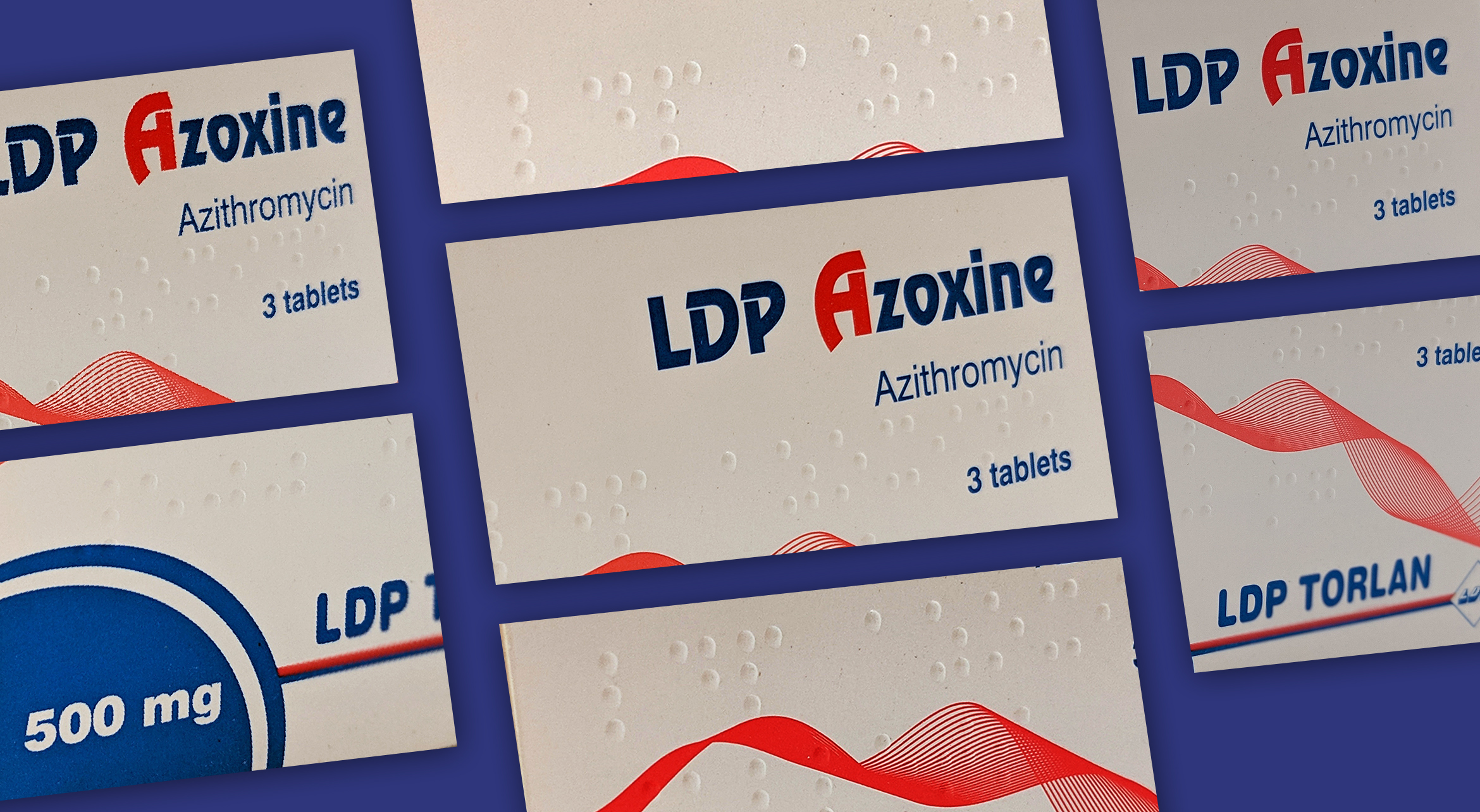

Printers must balance functionality and appearance, which may increase costs by 5-25%. Incorrect spacing or misplaced Braille dots can lead to serious consequences, especially in the pharmaceutical industry.

Braille on packaging provides blind individuals with essential information on consumer products, medical packets, cosmetics, and more. It enhances their safety, independence, and freedom of choice.

The major challenge is that Braille takes up space. Therefore, businesses must prioritize essential information to include in Braille on packaging to avoid clutter and maintain readability.

Organizations must verify word spacing, character spacing, line spacing, number of dots, characters, and lines with horizontal and vertical dot spacing to ensure the accuracy and consistency of Braille.

Braille, as an assistive technology, has been essential for over 200 years, and its use in packaging ensures the independence of visually impaired individuals. The global awareness of its importance is driving its increased adoption in the packaging industry.