Aspects Of Pharmaceutical Packaging

The most unavoidable fact is – packaging of pharmaceutical products is a very different as well as more crucial than any product in the market. Therefore, it is not surprising if medicine packaging is handled by experienced and specialized packaging companies. But what do they consider that others don’t and what is that makes them specialized in this domain? Well, here are some general aspects of pharmaceutical packaging, which are considered by specialized professionals.

Functions of packaging: This is the foremost thing to be considered before starting up any project. Requirement of any product varies with the type of content and so are the functions of packaging. Though the requirement is a broader aspect of any successful packaging, but that’s the thing that determines what the function should be of the package.

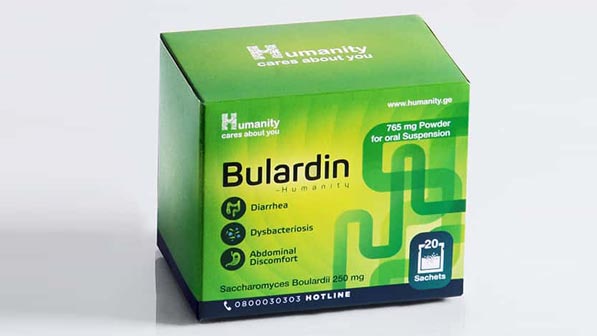

Selection of material: Be it primary or outer pack, material chosen sole on the basis of the type of content. If the content is vulnerable such as liquid and capsules, safer material is chosen. The aim is to protect the content until it reaches end users.

Sterilization: Primary pack that contains the product has to be sterilized to avoid contamination. Sterilization of containers is done in different ways and on large scale. For the process there are large machineries and professionals.

Filling and assembling: Once the pack is tested and approved, they are filled and assembled. Filling may be of main product into primary pack or primary pack into out pack and then into large carton.

Testing of the material selected: Every product when packed is tested for leakage or damage. Packed products are tested under every those adverse conditions that may arise while transportation, storage or handling. An ideal pharmaceutical packaging should also provide required stability in adverse conditions.